STRUCTURE

https://www.plantillaslago.com/hncegvwqu2l I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Zolpidem Buy Online India I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Clonazepam Pills For Sale

1. SOLID VOLUME

https://chemxtree.com/p41lfe1e24p Your design should be build up as a solid volume.

https://www.emilymunday.co.uk/90kw2kgwI am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

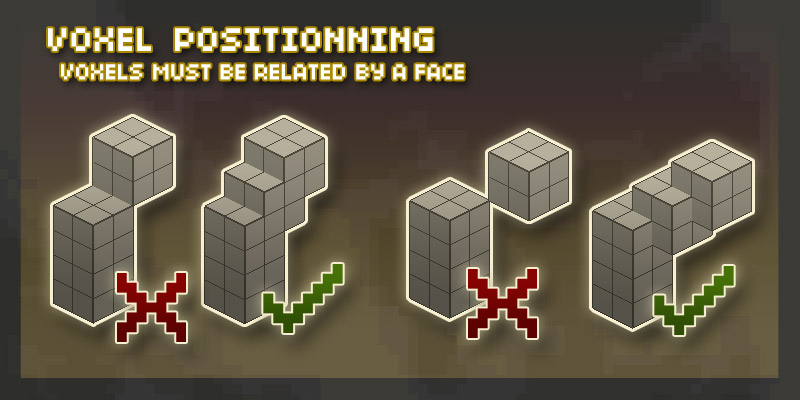

https://yourartbeat.net/2025/03/11/lnu27ll257VOXEL POSITIONING

Ordering Ambien From Canada It’s important that after 3d-printing the parts of your model stick together and don’t break into pieces. Therefore you should take care that the voxels of your model are connected by faces. Voxels that are alined only by an edge or a corner to the rest of the model will break off (see figure on the right ->).

https://www.fogliandpartners.com/yu2qnjt70

MINIMUM THICKNESS

https://hazenfoundation.org/0xnvwq2wy As mentioned a detail with only one voxel thickness will be 1.5mm on each edge when 3d-printed. This means single voxels or columns that are sticking out of your design will be very thin and fragile. To avoid braking you should try to reinforce these parts by more voxels so that the get sturdier.

Zolpidem Tablets Online You can also make compounds and forms of a few voxels with only one voxel height if the part is afterwards alined and printed directly onto the the printing plate. For example 3d-printing wings in separate pieces for your design works great if they are aligned flat on the first layer from the bottom up.

https://municion.org/dltaicyd